Control Systems

Handling Adversity

Everyone gets knocked down sometimes, what really matters is getting back up- and there are very few better approaches to getting back up than a PID controller. Today, we’ll be looking at how we can use this to keep our drones steady.

On the simplest level, we know where our drone should be (this will just be the signal from the controller) and we know where it is now (sensor fusion). So how can we close this gap?

Let’s look at the actuators we have on hand: 4 brushless motors with propellers (they aren’t just for cooling; I lied in the last workshop). We can break this down into two parts: which motors to spin, and how hard?

WARNING:

DO NOT OPERATE THE DRONE WHEN NOT FITTED WITH GUARDS

DO NOT POWER UP THE MOTORS WITHOUT WEARING GOGGLES

DO NOT POWER UP THE DRONE UNLESS IT IS MOUNTED TO THE TEST STAND

Due to the current limiting of the power supply, overly aggressive corrections may cause the supply to current cap- if this happens, the LED on the virtualbench will turn red. This means that your parameters are too high, and the drone will move unpredictably.

As per usual, supporting files on the Github. I've also included a nice web app to control the drone, so you can change parameters on the drone without reuploading your code each time.

Flight Dynamics

Like helicopters, our drones fly in a controlled manner by tilting in the direction they wish to travel. This means the thrust from the propellers is no longer going straight down, but also pushing the drone towards the direction it’s tilted in. As long as we can control the angle the drone is at, we can quite comfortably control where the drone goes.

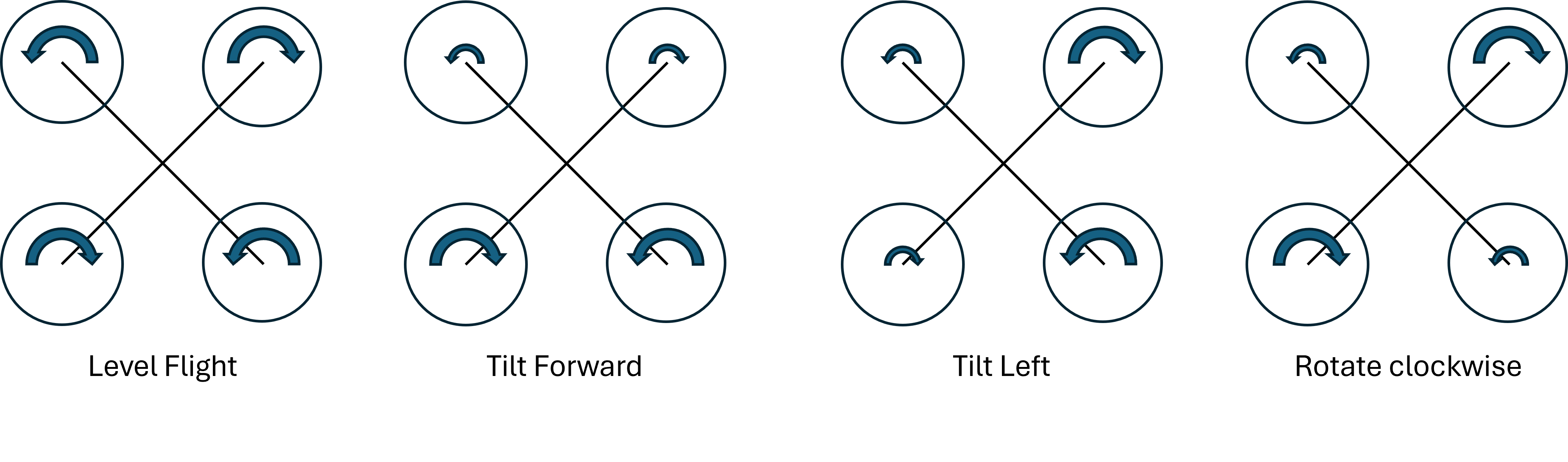

This diagram shows how the drone can control what direction it points in:

Remember, everything is controlled in terms of acceleration- When the propellers speed up, the drone will start to undergo rotational acceleration, and then as the thrust is directed backwards the drone will accelerate linearly. So if we’re controlling acceleration, how can we get the drone to hold at the right angle? Today, we’ll look at just one axis- roll.

Step 1: Setting up the Test Stand

You should have been provided with a semi-assembled test stand. This attaches to the 4 holes on the bottom of your drone, and only allows it to rotate in 1 direction.

You can use either bolts or zip ties to secure your drone to the stand.

You should have been given an XT30 connector which will fit the power plug on your drone. This will allow you to plug it into the virtualbench power supply.

Set the power supply to 14V 1A, and pay careful attention to the polarity when you connect it up to the drone. Don’t power it on just yet.

Upload controlSystemsTester.ino to the drone, and controlSystemsTransmitter.ino to your dev board. You should see that each one will print out a MAC address- put these into each other's code, and re upload again. Your system should now be set up.

To test everything is working, WITH THE ESC NOT CONNECTED TO POWER, Try hitting RUN CYCLE. If everything is wiorking properly, you should see the graph starts to draw some data. If not, try closing the tool, then opening the arduino IDE. Open and close the serial port, then try again.

PID controllers

So in our system we have a sensor, a microcontroller and an actuator. How can we take a number from the sensor, do some maths on it in the microcontroller and then send a number to the actuator?

Proportional control

A basic approach would be to take our current angle and our target angle to find the difference between them, and then send this signal to the actuator. Here’s what that might look like in code:

Float kP = 0.5;

Float P = kP * (currentAngle – targetAngle);

accelerateRotationSpeed(P);

If we’re in the right place, P will be zero and we won’t do anything. If we’re a little off, we’ll send a little power to the motor to correct it. If we’re really far away, we’ll send a lot of power to it. The term kP is something we can turn up or down to adjust how powerful a correction we apply.

This is a pretty good start, and for systems simpler than a drone this may very well be all we need. Try it out.

Step 2: Applying P Correction

Flash both the drone and your controller with their respective firmware, exchange their MAC addresses and connect up to the web interface. Time to move some air.

Hit connect and then hit run cycle. The drone should power up, but it won’t do much. To make it start responding, adjust the P slider and then hit run cycle again. Don’t adjust the other sliders just yet.

How does the drone respond to the different levels of P control? Can the drone have good performance with just this?

Too much or not enough

You’ll probably observe that the drone either doesn’t have enough power to get level, or it will overshoot and violently rock back and forth. This is because a proportional controller acts like a pendulum: We’ll keep accelerating until we hit the zero point, but we won’t stop moving- we’re controlling acceleration, not velocity here. This means we’ll overshoot and fly past the target. Now we’ll start accelerating the other way. And again. And again.

This is an unstable system, which is very bad and not good. If only there was a term which had a… dampening… effect.

Derivative control

For this, we’ll take into account how fast we’re going towards the target. Here’s what this looks like, added to the previous logic:

Float P =kP * (currentAngle – targetAngle);

Float D = kD * angularVelocity ;

accelerateRotationSpeed(P-D);

Now, if we’re really far from the target but moving towards it very fast, P and D will cancel out and we’ll just allow it to go ahead. If we’re almost at the target but moving to overshoot it, we’ll start pushing in the opposite direction to slow us down, and land nicely on the target. Also, if something external tries to move the drone, the D term will detect and react to this before the P term can. Very nice!

Step 3: Adding Dampening

Set the P term high enough that the drone is unstable, and then start to try increasing the D term. What happens as you increase it higher and higher? Remember, the gyro is sensitive to noise and these plastic frames do little to supress it. See how quick and smooth a response you can get out of a PD controller.

Hanging around

What happens if the drone is heavier on one side than the other, and we’re just using the PD controller?

Perhaps the unbalance is equivalent to a fixed accelerateRotationSpeed(-3). What this means is that the drone will be still when P-D=3… but if the drone is still, D will be zero so that 3 must be coming from the P term. For the P term to not be zero, that means the drone can’t be level… so the drone will come to rest at the wrong angle. This is pretty bad. Luckily, it’s and easy fix:

Integral control

To fix this, we’ll add another term which will slowly ramp up as long as the drone is not level. Here’s what this looks like in code:

Float P = kP *(currentAngle – targetAngle);

Float D = kD * angularVelocity;

I = I + kI * currentAngle;

accelerateRotationSpeed(P+I-D);

So now, the I term will keep on getting bigger and bigger as long as the drone is not level. Eventually, it should be big enough to balance out the unbalance and ensure the drone is fully level. The drone should now be fully controlled.

Step 4: Adding Integral

Take your stable PD controller and slowly increase the I term. See if the drone can be bought to fully level, with minimal vibrations. If the I term gets too high, you might see that the drone starts to oscillate around level due to the I term ramping up too fast.